Smart Mini Factories for Pharmaceutical Production

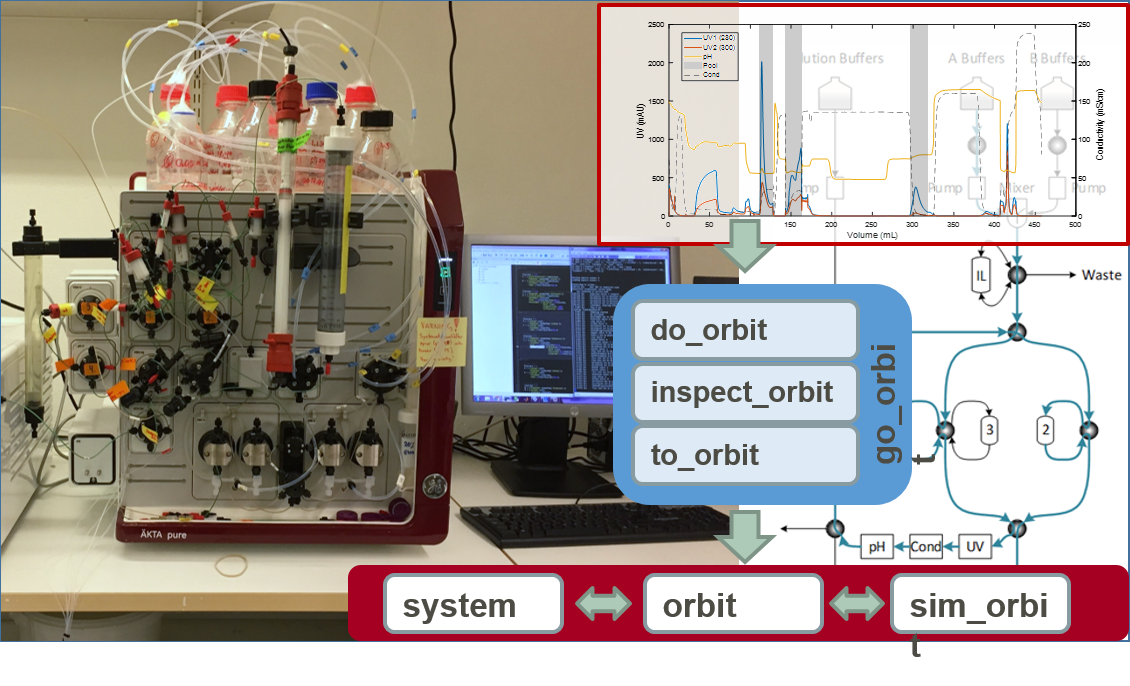

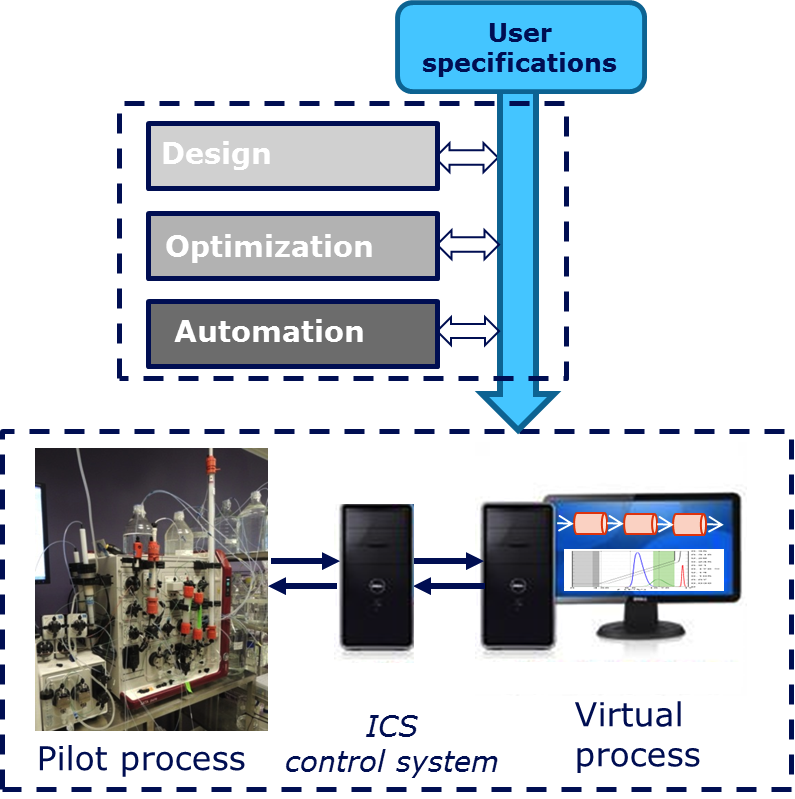

The demonstration will show that industrial digitization makes it possible to implement advanced production on a small scale in environments where access to expertise and ability is limited. The pilot will demonstrate that the production of biological drugs can be performed autonomously and effectively in places that need medicines but lack production skills. Examples of such environments are clinics, development labs and small businesses. These smart mini factories consist of a physical general and adaptive equipment and a virtual process designed by a virtual autonomous design method.

The second part of the project consists of development work packages and one industrial implementation phase.

|

Package 1-4 (2016): The physical factory is demonstrated. A open Package 5-7 (2017): The development of a digital factory which is Two industrial case studies will be used during the development. Package 8: The concept for small-scale production of pharmaceuticals |

|

The project focuses on demonstrating new process solutions adapted to the need for scaling in the production process. With scaling being a key element of the industry for biological drugs, new technology needs to be adapted to the changing needs during the production process. Smart process solutions enable smart product development.

With access to virtual tools, smaller actors can access expertise and ability to produce in an advanced and effective manner. The final product will also expand the ability with equipment suppliers and open up the market for new suppliers, including software companies.

The project is co-financed by VINNOVA, Lund University and industrial partners Sobi, Novo Nordisk A/S and Modelon AB.